- HVAC–From the above it is clear that HVAC industry is not limited to maintaining comfortable environment inside a space alone.

HVAC involves handling of air to maintain desired conditions inside a closed space .The maintenance of a specific temperature,humidity ,cleanliness levels are necessary for a particular process to take place in a closed space .

Typical applications of HVAC are :-

-

- Commercial office space – Only a desired temperature is to be maintained around the year

- High End office spaces and residences – Temperature and PM 10 and PM 2.5 cleanliness levels

- Operation Theatres and ICUs in Hospitals – Temperature , humidity , cleanliness levels and to prevent contamination/influx of bacteria and viruses from adjoining areas

- Pharmaceutical applications (medicines manufacturing )- Temperature , humidity , cleanliness levels and to prevent contamination/influx of bacteria and viruses from adjoining areas

- Shop Floors in Manufacturing Industries – To maintain a comfortable environment for workers with temperatures in range of 28-32 deg C (air cooling application based on evaporative cooling )

- Metal casting ,forging and chemical industry – Removal of heat and fumes generated during the process and influx of fresh air to maintain a healthy and safe environment for workers and other staff

- Malls , Restaurants , Theatres and Multiplexes – To maintain temperature and humidity levels for a large gathering of people

- Basement Fresh air and smoke exhaust systems- These are mandatory requirements for obtaining NOC from Fire Department

- Multi storeyed buildings- Smoke exhaust systems and lift lobby pressurisation to keep the staircase and lift lobby free from smoke to facilitate easy evacuation of people in case of fire emergency

- Server rooms– Desired temperature and humidity levels to be maintained 24 x 7 x 365 to prevent damage to costly serve components .

- Cold storages – Long term storage of perishable commodities

- Airconditioned trucks for transfer of perishable food items

Most of the above applications require high levels of technical skills for deigning , installation and commissioning of a suitable HVAC system catering to specific requirements .

DEVAGYA ENGINEERING has been promoted to specifically provide this type of customised solutions to its esteemed customers in HVAC and MEP

DIFFERENT TYPES OF AIRCONDITIONG SYSTEMS

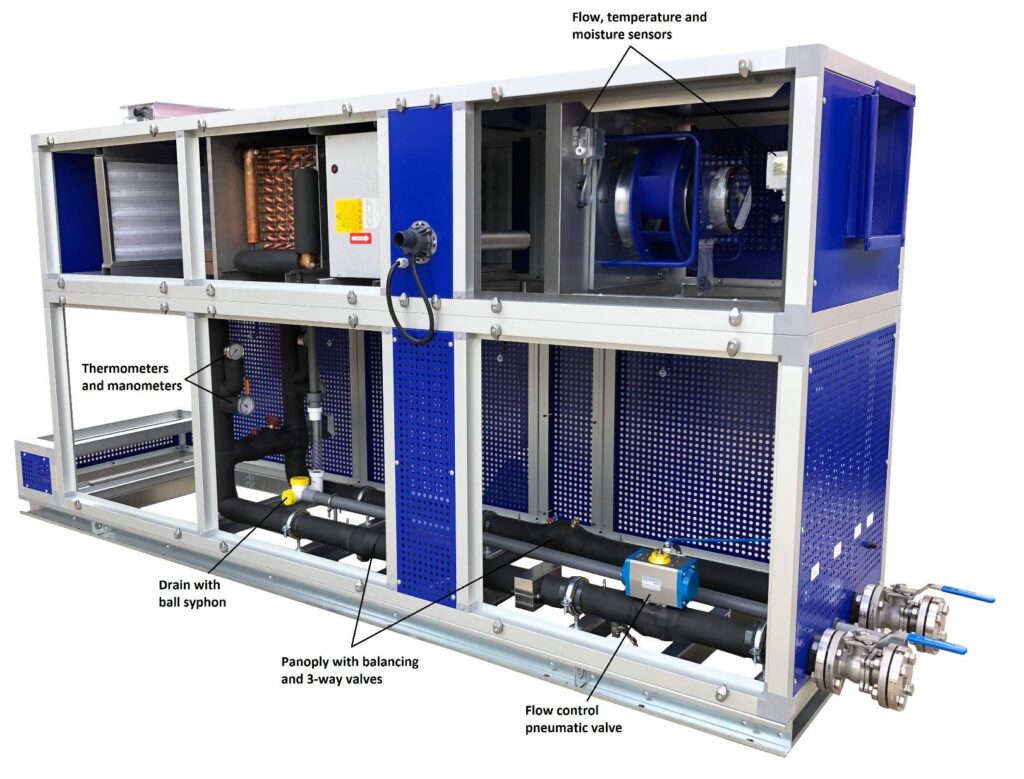

- Central Airconditioning system – This type of system involves a central unit to cool media like water(technically referred as Chilled Water system ) or refrigerant(technically referred as Direct expansion system ) . The water / refrigerant is then circulated to various areas through metal pipes .The individual areas have dedicated small heat exchangers , commonly referred as Air Handling Units (AHU) which cool the air to be fed to the different spaces . These AHUs may be connected to ducts to distribute the conditioned air .

These AHUs have different type of filters depending on the cleanliness levels to be maintained

After cooling the supply air , the cooling media (water / refrigerant ) is pumped back to the central unit. The central cooling unit removes the heat from the media by causing it to come in contact with external media (air or water ) . Thus the cooling units are commonly referred to as air cooled and water cooled systems

2.VRV (Variable Refrigerant System ) – In layman terms , this system is just like a multiple split airconditioning system with one outdoor unit and multiple indoor units . The volume of refrigerant flowing through individual indoor units is varied depending on the airconditioning load in respective spaces . The variable flow is achieved by a microprocessor based controller .

The benefits of the VRF system is positioned in between the large capacity chiller and the small capacity split AC. The VRF system provides great flexibility while keeping good energy efficiency. It is an all-arounder when it is designed properly.